BackDrillTop - apply to vias/pads that have a top side back drill.To scope a design rule to control the solder mask opening at a back drill hole site, you can use the query keywords shown below. For example, if you only want to back drill the vias and not the thru-hole pads, then you could change the rule scope to InNetClass('IO') and IsVia. To further limit the back drilling operation, tighten the rule scope. The holes that are actually back drilled will depend on which layers those signals are routed on, and which back drill pairs have been defined - if a hole has no connections on the layers within the back drill layer range, then that hole will be back drilled. The scope of the rule defines which objects this rule must be applied to, this rule targets vias in the IO net class.įor example, if the scope is InNetClass('IO'), then all vias and pads in those nets can potentially be back drilled. Typically you only back drill selective nets, such as the high-speed nets, in which case the scope could be something like InNet('Clock'), or InNetClass('HighSpeedNets'). The scope of the design rule defines which vias or pads are to be drilled.

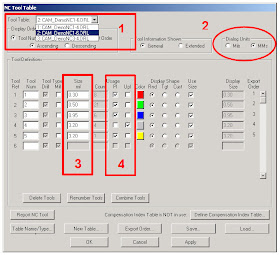

#CAM350 TROUBLE READING ALLEGRO NCDRILL FILE SOFTWARE#

You instruct the software that there are holes to be back drilled by adding a Maximum Via Stub Length (Back drilling) design rule. Remaining NFPs can be removed from any design by running the Tools » Remove Unused Pad Shapes command.Ĭlearance values for polygons and power planes are calculated from the back drill diameter, insuring that a back drill does not drill the copper of a surrounding polygon or power plane.

Non Functioning Pads that are on a layer that is to be back drilled, are automatically removed at each back drill hole site. If a via or pad is not used on a signal layer, that unused ring of copper is often referred to as a Non Functioning Pad (NFP). The diameter of the drill used for back drilling is defined by Via/Pad hole size + 2 x Oversize setting in the applicable Maximum Via Stub Length (Back drilling) design rule.The depth that the hole is back drilled to is defined by configuring a drill pair, that specifies the start and stop layers for back drills from that side of the board.Note that this stub length is not a drill setting, it is the value the software uses to check for remaining stubs during a batch DRC. Defining a Maximum Via Stub Length (Back drilling) design rule which defines the nets of interest, and also the maximum allowable stub length.It offers lower cost than the sequential lamination technique used for blind and buried vias.

Most commonly used for vias, and also for press-fit backplane connectors, back drilling provides a cost-effective solution to help manage the signal quality for high-speed signal paths. Note that both vias have some remaining stub. To remove the stubs, the via on the left is back drilled from the top side, the via on the right is back drilled from both sides. These stubs can be removed by performing a second drill pass, where the barrel is drilled out to an exact depth, as shown in the adjacent image. This unused portion of copper barrel acts as a stub, creating reflections if the signal switches at high speeds. In printed circuit board design, a via stub is a length of copper barrel that projects beyond the the signal layers used to route that signal. These stubs can be removed using controlled depth drilling. The via is used to connect between the 2 internal layers, resulting in un-used barrel (stubs) above and below. Allowing for fabrication and material variations, a good fabricator can back drill holes to leave a 7mil stub, ideally the remaining stub will be less than 10mil. The holes are back drilled to a controlled depth, close to, but not touching, the last layer used by the via. These stubs can be removed by re-drilling those holes after the fabrication is complete, with a slightly larger drill. If the signal layer usage results in a stub being present, and the stub is long, then that distortion can become significant. When a high-speed signal travels between PCB layers through a copper barrel, it can be distorted.

0 kommentar(er)

0 kommentar(er)